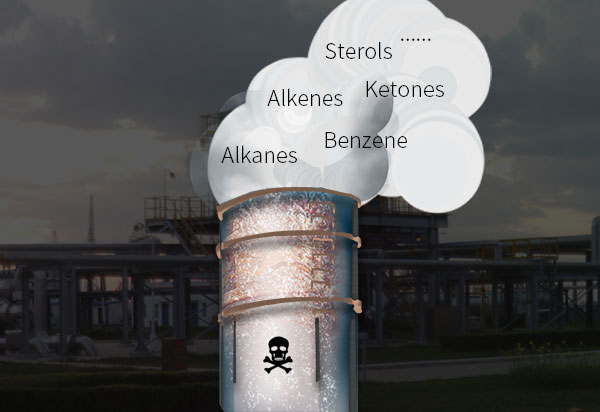

Heating waste gas from heating enterprises,

All kinds of compound gases from the production of petrochemical enterprises,

Gas leakage from pipeline transportation,

··· ···

These gases leaked into the atmosphere, have caused varying degrees of pollution to our living environment, and even explosion and other safety accidents.

It's time to make a change!

Based on high sensitivity HgCdTe MWIR detector, Global Sensor Techology has developed a complete set of solutions for gas leakage detection, including C330M-G gas detection detector and EYAS330G Special AD module for gas detection and GAS330 gas leak module can transform invisible gas into visible infrared image by infrared thermal imaging technology, which can effectively monitor the leakage of methane, hydrocarbons and other volatile organic compounds (VOCs) in the process of production, transportation and treatment of petrochemical enterprises, and further respond to the government's environmental protection Gas330 is suitable for atmospheric environment monitoring, natural gas transportation pipeline, petrochemical plant, refinery testing and other fields.

Special detector for gas detection

Gas leak detection technology is based on the principle of infrared absorption spectrum. Different gases have corresponding characteristic absorption peaks. Different gases can be detected by measuring the infrared absorption wavelength according to the different absorption degree of different gases. Different gases will have an absorption peak at different wavelengths, while the absorption peaks of methane, hydrocarbons and other volatile organic compounds VOCs are just in the range of mid wave infrared absorption spectrum. By professional infrared detector, invisible gases can be transformed into visible infrared images, so that "gas leakage" is inevitable. Therefore, the key to achieve clear gas imaging is to have advanced MWIR detectors. Global Sensor Technology has a completely independent intellectual property rights of the infrared detector mass production line, the first in China with a variety of models of medium wave cooled infrared detector production capacity.

Gas330 gas leak module is based on C330M-G middle wave COOLED infrared detector with NETD ≤ 15mk, frame rate of 30Hz and effective pixel rate of more than 99%, which ensures that it has higher gas detection sensitivity and smoother gas infrared imaging picture. The detector has fast response rate, strong gas pertinence and good environmental adaptability. It is especially suitable for the detection application scenarios where the staff can not get close to the closed narrow space and the gas velocity is slow and the gas concentration is low.

A variety of gas types can be detected

Due to the wide range of application scenarios of gas leak detection, including but not limited to environmental monitoring stations, petrochemical parks, hazardous chemicals warehouses, oil and gas pipelines, etc., the types of gas emissions and gas leakage in various places are also various. The spectral response band of Gas330 is 3.2 ~ 3.5 μm. according to the infrared absorption spectrum characteristics of gas molecules, there are many kinds of gases in its detectable range, which can realize the effective leakage detection of many kinds of gases.

In addition, the spectral response band of Gas330 can be customized in the medium wave range of 3 μm to 5 μm according to customer requirements, which means that more kinds of gases will enter its "olfactory range". The more kinds of gas that can be detected by gas detection equipment, the better its compatibility performance and the wider its terminal application field.

Go Top