Infrared thermal imaging has become an indispensable tool in various fields, including industrial inspections, surveillance, medical diagnostics, and more. The ability to capture and analyze infrared radiation helps in detecting anomalies, temperature distributions, and invisible patterns. One critical aspect of an infrared thermal imaging system is the pixel size of the detector, which directly influences the image resolution and sensitivity.

Pixel size refers to the dimensions of individual detector elements within an imaging sensor. Some people also refer to this size as pixel pitch or pixel center distance, which is the physical distance between the centers of adjacent pixels. It includes 30μm, 25μm, 17μm, 12μm, 10μm, 8μm, and so on. The pixel size determines the smallest resolvable detail and the spatial resolution of the resulting infrared image. Generally, smaller pixel sizes allow for higher resolutions and more accurate temperature measurements. However, the choice of pixel size is a balancing act between spatial resolution, sensitivity, and cost-effectiveness.

Infrared thermal imaging detectors with smaller pixel sizes offer higher spatial resolutions. Smaller pixels can capture finer details and provide more precise temperature measurements. This is particularly important for applications that require detecting small variations in temperature or identifying subtle features. With higher resolutions, it becomes possible to capture more information within the field of view, enabling better analysis and interpretation.

Infrared detectors achieve infrared thermal imaging by the photoelectric conversion effect of each pixel on the focal plane. The pixel size directly affects the size, cost, and imaging performance of the infrared thermal imaging component, making it an important parameter.

With the widespread application of infrared thermal imaging technology, there is an increasing demand for higher performance. As a result, the pixel size of detectors has been decreasing from 45/30/25μm to 17/15/12/10/8μm.

Why is the pixel size becoming smaller?

1.Increase chip yield and lower production costs

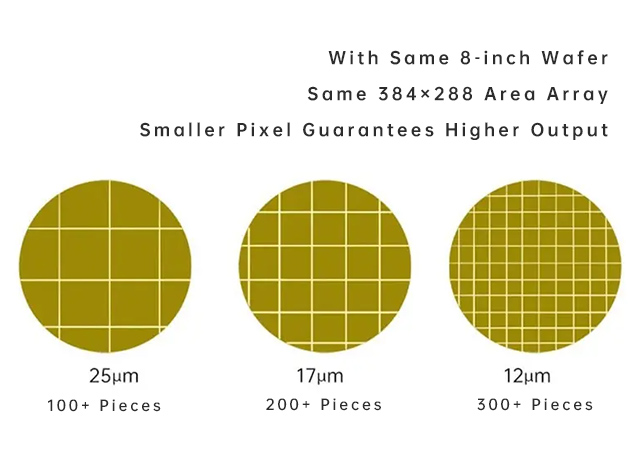

For example, on the same 8-inch wafer, a wafer with 12μm pixel pitch can have several times higher yield compared to a wafer with 25μm pixel pitch for the same 384x288 array specification.

Smaller pixel size leads to higher yield on the same 8-inch wafer. For example, 25μm can have a yield of over 100 pieces, 17μm can have a yield of over 200 pieces, and 12μm can have a yield of over 300 pieces.

2.Promote miniaturization and cost reduction of thermal imaging systems

With the same field of view, smaller pixel size results in a smaller optical system, promoting the miniaturization and cost reduction of thermal imaging systems.

3.Improve infrared camera resolution

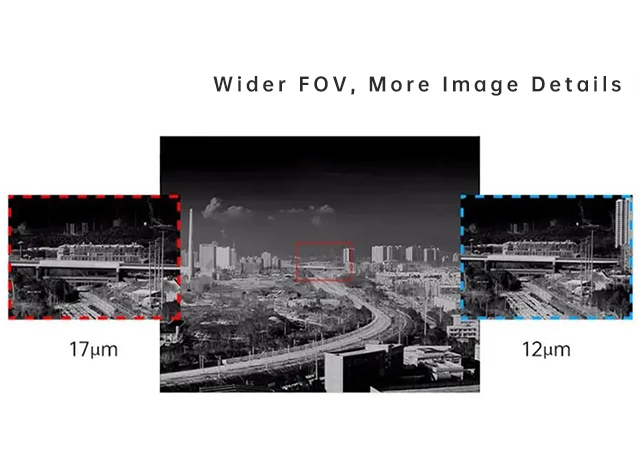

With the same focal plane size, smaller pixel size allows for more pixels, resulting in higher resolution, wider field of view, and broader vision.

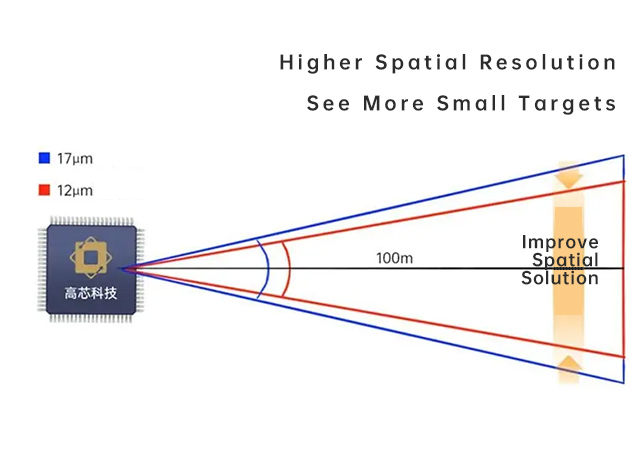

4.Enhance spatial resolution of infrared detectors

Under the same observation distance conditions, smaller pixels can achieve higher spatial resolution and detect smaller targets.

5.Enable longer detection distance for infrared detectors

Under the same target size, a larger focal plane array with more pixels can achieve a longer recognition distance.

Go Top