Being proactive is the primary attitude we should adopt when dealing with chemical safety issues. However, traditional methods of preventing chemical accidents have many shortcomings, the most significant being the inability to detect potential hazards in a timely manner. Take traditional visible light video surveillance systems as an example, they face the following problems:

1.Aging and unreliable video monitoring systems, with difficulties in updates and maintenance.

2.Unstable transmission modes, frequent video freezes and disruptions.

3.Video surveillance systems are vulnerable to intentional sabotage.

4.Multiple and scattered video surveillance points make maintenance challenging.

5.Passive detection through manual monitoring leads to delayed detection and low efficiency.

6.Limited detection distances of existing cameras cannot meet the requirements of comprehensive and continuous monitoring.

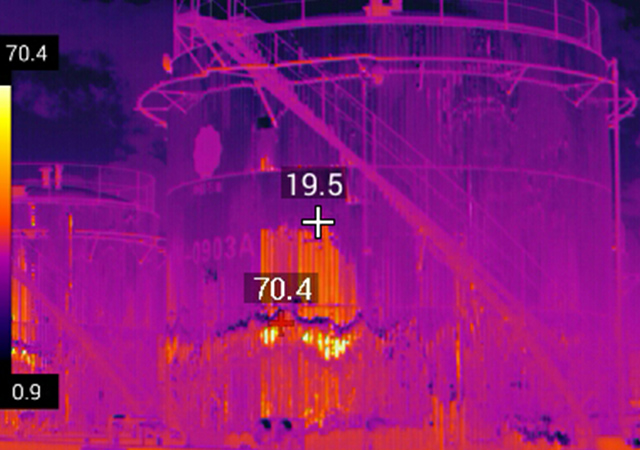

By reviewing past safety incidents, it can be observed that accidents are not without warning signs. Temperature is an important indicator in the production processes of hazardous chemicals. Temperature abnormalities often accompany old equipment, abnormal voltages, and undiffused accident points, which are not visible to the naked eye.

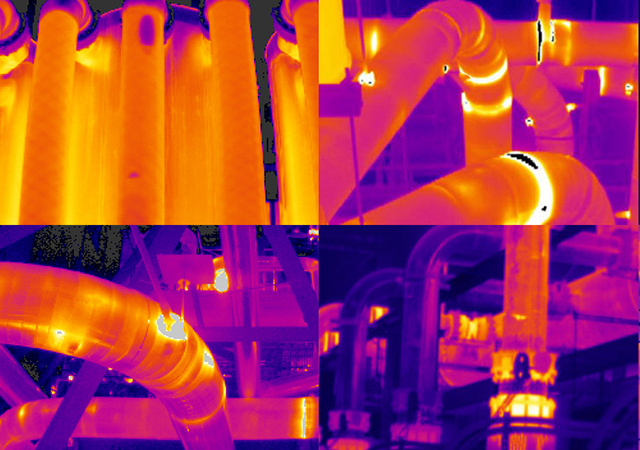

However, these temperature abnormalities can easily be detected by thermal imaging monitoring systems. Wuhan Global Sensor Technology offers thermal imaging solutions specifically designed for the chemical industry, which feature rapid temperature measurement and wide-range temperature measurement capabilities. By using infrared thermal imaging camera cores for monitoring, chemical companies can identify safety hazards and reduce loss of life and property.

Taking the professional temperature analysis function as an example, traditional visible light video surveillance systems rely on human monitoring, which can be considered a limited method. However, humans are different from machines, as even with long periods of focus on monitoring screens, they may not promptly identify danger signals, thus missing the “golden warning time.”

On the other hand, the analysis function in thermal imaging solutions not only enables real-time alarming of danger signals but also utilizes the core judging factor of “temperature” to enhance the reliability of warning signals and reduce accident risks.

Based on infrared camera module/core developed by Wuhan Global Sensor Technology, the infrared products are developed into 3 forms and have been successfully applied with mature solutions:

C330M-G infrared detectors suitable for integration by experienced experts

EYAS330G infrared AD module reduces the difficulty of developing based on infrared detectors

GAS330 infrared camera core with easy development and rapid market launch

Through the application of infrared thermal imaging technology, chemical companies can promptly detect potential hazards and take effective preventive measures before accidents occur, ensuring the safety and stability of production processes. The promotion and application of infrared thermal imaging technology will further enhance the safety level of the chemical industry, safeguarding the well-being of employees and equipment, and promoting the sustainable development of the industry.

Go Top